In the world of manufacturing and production, precision and efficiency are key to maintaining high-quality products and meeting tight deadlines. One machining process that has gained popularity due to its unique advantages is centerless grinding. This technique offers several benefits that can improve production performance and product quality. In this article, we will explore the top benefits of using centerless grinding for your production needs.

What is Centerless Grinding?

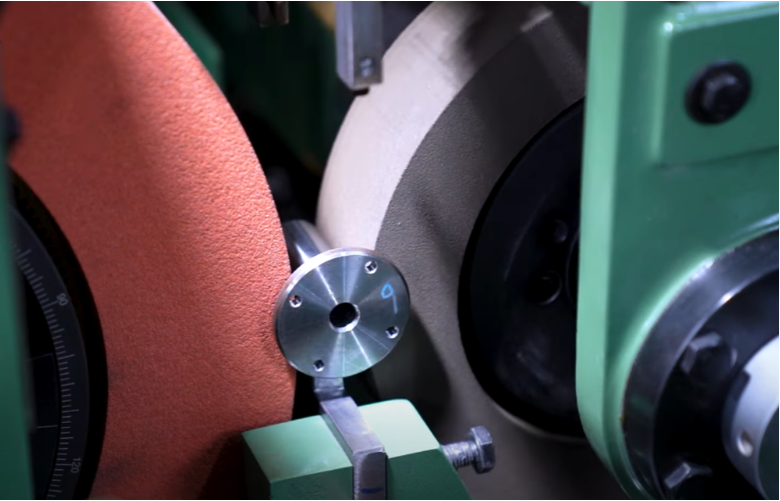

Before diving into the benefits, it is important to understand what centerless grinding is. Unlike traditional grinding methods where a workpiece is held between centers or chucks, centerless grinding supports the workpiece between a grinding wheel and a regulating wheel without the need for centers. This allows the workpiece to rotate freely while being ground to precise dimensions and finishes. This method is often used for cylindrical parts and is highly efficient for high-volume production.

Enhanced Precision and Accuracy

One of the main advantages of centerless grinding is its ability to deliver exceptional precision and accuracy. Because the workpiece is supported and rotated between two wheels, it can be ground uniformly along its entire length. This leads to consistent dimensional accuracy and roundness, which is essential for parts that require tight tolerances. The process minimizes errors often caused manual handling or misalignment in traditional grinding methods.

Increased Production Speed

Centerless grinding is known for its fast production capabilities. Since the workpiece does not need to be clamped or fixed between centers, the setup time is significantly reduced. Additionally, multiple parts can be ground in continuous succession without interruption, making it ideal for large production runs. This increased speed helps manufacturers meet deadlines and reduce lead times, which is crucial in competitive markets.

Improved Surface Finish

The surface finish of a machined part affects its performance and appearance. Centerless grinding offers an excellent surface finish due to the controlled movement and constant contact between the grinding wheel and the workpiece. This smooth finish can reduce the need for additional polishing or finishing operations, saving time and cost in the production process.

Versatility for Different Workpieces

Centerless grinding is highly versatile and can accommodate a wide range of workpiece sizes and shapes. It is particularly effective for small to medium-sized cylindrical parts, such as shafts, pins, and tubes. This flexibility makes it a valuable option for various industries, including automotive, aerospace, and medical device manufacturing.

Reduced Operator Skill Requirements

Unlike some machining methods that require highly skilled operators to maintain precision, centerless grinding is more forgiving and easier to automate. The setup is straightforward, and once parameters are set, the process can run with minimal supervision. This reduces the dependency on specialized labor and allows companies to maintain consistent quality with less manual intervention.

Lower Production Costs

Centerless grinding can contribute to lower overall production costs. The combination of faster cycle times, reduced setup, and less need for manual adjustments means that manufacturers can produce more parts in less time. Additionally, the improved accuracy reduces scrap rates and rework, which further saves materials and labor expenses. Over time, these savings add up to a more cost-effective production process.

Enhanced Process Automation

Because centerless grinding is a continuous and consistent process, it is well-suited for integration with automated systems. Many modern production facilities use robotic loaders and unloaders along with centerless grinding machines to create fully automated production lines. This automation improves throughput and reduces human error, supporting higher quality and efficiency.

Conclusion

Centerless grinding offers numerous benefits that make it a valuable machining option for various production needs. Its ability to deliver high precision, increased speed, excellent surface finishes, and cost savings can greatly improve manufacturing operations. Whether you are producing small cylindrical parts or require large-volume production, centerless grinding provides a reliable and efficient solution. Adopting this technology can help your business stay competitive ensuring quality, reducing production times, and lowering costs.

If you are considering ways to enhance your production process, exploring centerless grinding technology is definitely worthwhile. With its unique advantages, it can be a key factor in achieving your production goals efficiently and effectively.